Surface finishing of stainless-steel cookware is an important factor in quality, durability, and consumer safety. Traditionally, polishing techniques have become more well-known in recent years for the hidden hazards they pose, prompting manufacturers to reevaluate their methods. Usually, cookware manufacturers use mechanical polishing processes with polishing waxes to give an attractive, shiny look. But increasing concern over consumer health and environmental sustainability is forcing the cookware industry toward electropolishing, a safer, greener, and more potent alternative.

The Basics of Manual Mechanical Polishing

Mechanical polishing has been a popular finishing process for cookware, particularly stainless steel types. Starting with abrasive belts or other grinding wheels that clean and smooth surface imperfections. Afterwards, specific wax compounds called polishing wheels bring a glossy look to the product.

Standard polishing waxes usually contain abrasive materials, fatty acids, waxes, silica, aluminum oxide, as well as chemical additives that may be hazardous to health. Although these polishing compounds effectively yield a visually aesthetic result, they leave residual deposits that pose potential dangers to consumers.

Challenges with Conventional Polishing Methods

While often used, current-state mechanical polishing methods have several serious limitations:

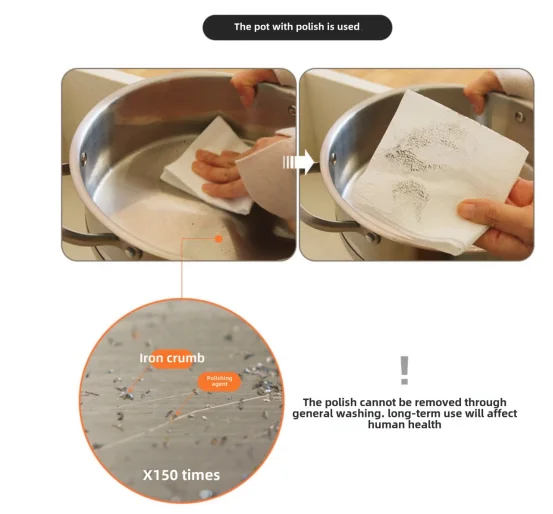

Residue Contamination: Polishing residue can leave behind black stains on the cookware that do not come off during even the most diligent cleaning process. These residues, although not visible to the naked eye, are notoriously hard to remove completely.

Harmful Effects: The World Health Organization (WHO) has classified many polishing residues as Group 2A carcinogens, which means they are probable to cause cancer if consumers are exposed to them over a long period of time.

Lack of Cleaning: Conventional household cleaners and detergents can rarely remove these residues regardless of how many times the food surface is cleaned and rinsed, thereby exposing consumers to long-term contaminants and increasing their health risk.

Cost Savings for Manufacturers: Even with the health risks associated with polishing methods, manufacturers still select traditional polishing methods because they are cost-effective, very efficient, fast, and suitable for large-scale mass production.

What is Electropolishing?

When applied to a method called electropolishing, this can prove to be a safe and effective alternative to traditional mechanical polishing methods. This process works by immersing stainless steel cookware into an electrolyte bath and running an electrical current through the solution. This electrochemical process effectively removes microscopic imperfections and contaminants from the surface of the cookware, resulting in an ultra-smooth, clean, and contamination-free finish.

The process of electropolishing, which offers polishing and decontaminating in one, leads to an ultra-smooth surface and a distinct improvement in cookware hygiene, life, resistance to corrosion, and performance.

Benefits of Electropolishing

Electropolishing has a number of advantages over traditional polishing:

Enhanced Safety: Unlike traditional polishing, electropolishing does not leave a carcinogenic residue, which greatly lowers health risks from cookware.

A Chemical-Free Setting: Electropolishing, unlike traditional polishing processes, does not rely on the use of toxic chemicals such as Perfluorooctanoic Acid (PFOA), cadmium, or lead.

Improved Durability and Visual Aesthetics: Electropolishing creates a smoother, cleaner surface that resists staining and corrosion, improving the cookware’s durability and attractiveness.

Green Technology: Electropolishing is far more environmentally friendly, as it produces very small amounts of hazardous waste, creating a much smaller environmental footprint.

Enhanced Hygiene: The smooth, contaminant-free surface that comes as a result of electropolishing helps prevent the build-up of bacteria, increasing the hygienic quality of cookware.

Cost and Market Benefits of Electropolishing

While initial costs are usually higher, the long-term economic initiatives of electropolishing are significant:

Lower Risk of Liability and Recalls: Cookware without harmful residues greatly reduces the potential for nasty product recalls and liability issues related to consumers’ health.

Increased Consumer Satisfaction: Improved product quality results in higher consumer loyalty and brand reputation, providing long-term economic benefits.

Market Differentiation: Electropolishing can help companies stand out from competitors in terms of safety, quality, and environmental impact.

Recommendations for Consumers and Industry

Companies need to adopt electropolishing not just as a superficial finishing capability but as a critical priority for long-term success and ensuring profitable partnerships. As with any growing brand aiming to establish consumer trust and market growth, brands need to build consumer awareness about cookware surface safety and communicate the importance and risks associated with traditional polishing and the advantages of electropolishing.

Consumers are demanding more transparency about the safety and environmental impact of what they buy. Manufacturers that make it clear that they have adopted electropolishing techniques will strongly influence purchasing decisions and lead the industry in terms of responsibility.

The Path Ahead: Responsibility from the Industry

This technology implementation is not just an upgrade but a step toward responsible business practices as well. Investing in safer, eco-friendly methods shows a commitment to consumer safety and environmental stewardship. Adopting electropolishing can contribute to a massive transformation in public health, sustainability, and product quality standards in the industry.

الخاتمة

Electropolishing is a natural progression in the cookware production process. This system effectively addresses the core aspects of consumer safety, environmental sustainability, and quality assurance. There are massive benefits to manufacturers and consumers alike by having electropolishing in high volume, which means adopting this technology will result in healthier, safer, and higher-quality cookware for generations to come. It is the imperative of the industry to stand behind this revolutionary technology, integrating corporate responsibility and promoting safer consumer practices to protect health and environmental sustainability.

Founded in 1998, Purecook is a leading global manufacturer of high-end electrolytically polished stainless steel cookware, focusing on providing safe, durable and environmentally friendly OEM & ODM solutions. With 30 years of manufacturing experience and advanced automated production lines, our products are exported to many countries and regions around the world and are deeply trusted by professional chefs, home users and the catering industry.

Purecook is committed to promoting the cookware industry towards higher quality and healthier development:

- Focus on polishing technology: Using electrolytic polishing process to create ultra-smooth, residue-free stainless steel cookware, improve food safety, reduce adhesion, and make it easier to clean;

- Healthy and harmless: Do not use traditional mechanical polishing wax to eliminate potential harmful residues, ensure that the surface of the cookware is 100% pure, and meet international food safety standards;

- Excellent durability: Select high-quality stainless steel materials, combined with precision polishing process, enhance corrosion resistance and wear resistance, and extend service life;

- High-end visual aesthetics: Mirror polishing and brushed polishing process are combined to provide an extremely smooth texture and modern and simple aesthetic design, making the cookware both functional and beautiful;

- Green and environmentally friendly manufacturing: Electrolytic polishing reduces the emission of chemical pollutants, meets the requirements of sustainable development, and creates a more environmentally friendly kitchen solution.

Purecook firmly believes that polishing process is not only related to the aesthetics of cookware, but also directly affects food safety and user experience.

With our excellent polishing technology, we bring cleaner, safer and higher quality stainless steel cookware to consumers around the world.

اتصل بنا

لا تتردد في الاتصال بناjoy@purecook.com

لا تتردد في الاتصال بنارقم 68 طريق شيانهوا رقم 68، قرية هواشياو، بلدة كايتانج، منطقة تشاوآن، مدينة تشا أوزهو، مقاطعة قوانغدونغ