Stainless steel products are all around us – from kitchen appliances to medical devices and industrial components. “This has led to a misconception that ‘real stainless steel is never magnetic’, which couldn’t be further from the truth.” Many consumers test the magnetism of stainless steel items to determine their authenticity and quality, believing that magnetic attraction means the product is inferior, counterfeit or mislabeled.

But this common wisdom, as anyone versed in metallurgy and the manufacturing of stainless steel knows, is a major oversimplification that is very misleading. That brings us to the complication about magnetic stainless in everyday life: The reality is, numerous authentic stainless-steel materials — even anti-magnetic ones — will create minimal magnetism in the right environments.

In this all-encompassing guide, we’ll clarify exactly why non-magnetic stainless steels — specifically, grades 201 and 304 — show magnetism, while also offering general advice to aid consumers and professionals alike in accurately interpreting and evaluating their stainless steel products.

The Magnetic Properties of Various Types of Stainless Steel

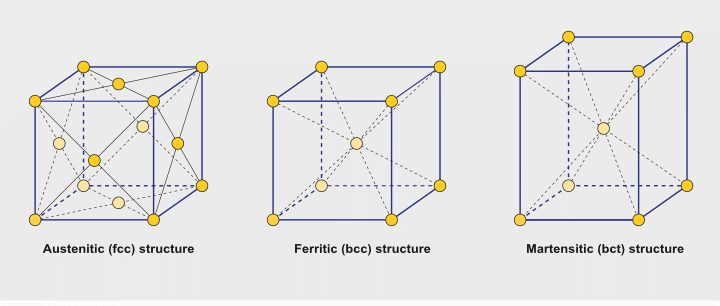

That said, the first consideration in stainless steel selection is that stainless steel is not one and the same material, but rather a family of alloys which are grouped by their crystalline structure. Stainless steels may be categorized based on metallurgical classification into three broad groupings.

Austenitic Stainless Steel

The ferromagnetic properties of these steels are more akin to those found amongst the common types (ex: 201, 202, 301, 304, and 316) which are normally not magnetized in the general sense, so they show non-magnetic to very weak magnetic behavior at room temperature. They have a face-centered cubic (FCC) crystal structure and are weakly nonmagnetic.

While consumers encounter all sorts of austenitic stainless steel products in abundance (304-grade kitchen items abound world-wide), the distinctions are there to be understood, and they explain why magnetism can vary so widely from one item to another, even of the same grade.

- Crystal structure: Face-centered cubic (FCC)

- Normal magnetism: Non-magnetic to very weakly magnetic

- Common in kitchenware, appliances, and food processing tools

- Even though considered “non-magnetic,” they can exhibit slight magnetism under certain conditions.

Ferritic Stainless Steels (e.g., 430)

- Crystal structure: Body-centered cubic (BCC)

- Magnetism: Naturally magnetic

- Less corrosion-resistant than austenitic grades but more affordable.

Martensitic Stainless Steels (e.g., 410, 420)

- Crystal structure: Body-centered tetragonal (BCT)

- Magnetism: Strongly magnetic

- Often used in knives and cutting tools due to hardness.

The Reason Austenitic Stainless Steel (such as 304) Can Become Magnetic

Effect of Alloying Elements and Metallurgical Variations

The austenitic phase of the commonplace grade 304 stainless steel, or “18-8,” which is an alloy of about 18% chromium and 8% nickel, is stable at room temperature. But even a slight release of nickel and/or chromium during production may cause unplanned formation of small amounts of ferritic or martensitic phases in the alloy. Both the ferritic and martensitic phases are magnetic and thus are responsible for providing some weak magnetic behavior to the steel.

For example, in the practical production environment, it is almost impossible to guarantee a 100% homogeneity of the alloy. Small differences in the smelting and cooling process result in something metallurgists call “chemical segregation”. Several iron-rich phases that are magnetically responsive liquidate visually enhanced areas. While such areas account for a small percentage of the alloy, their magnetic response can be detected by high-strength household magnets and cause consumers to unduly doubt product authenticity.

Cold Working, and Mechanical Processing Effects

Machining has an effect on everything, not just stainless steels — but is perhaps the most common reason a genuine non-magnetic stainless steel will become magnetic is cold working, also known as mechanical deformation. Cold working is the physical deformation of the metal below its recrystallization temperature, typical in manufacturing processes like rolling, bending, drawing, or stamping.

Austenitic stainless steels no matter their grade, such as 304, are non-magnetic in their solution phase; however, when cold-worked these steels undergo a partial transformation in crystal structure from non-magnetic austenite to magnetic martensite. More the deformation, the more local martensitic phase tends to develop, resulting in a higher magnetic response of the product. For example:

- A typical Φ76 mm stainless steel pipe will essentially not be magnetically attracted because the deformation during the forming process is very small.

- For instance, significant deformation occurs, and therefore, better magnetic attraction goes up remarkably when the same batch of steel is drawn into a fraction, such as Φ9.5 mm tube.

- Rectangular or square tubing undergoes even more deformation — especially at the corners — therefore showing more magnetism.

This phenomenon, scientifically known as strain-induced martensitic transformation, is well-known in the metallurgy world but can be misunderstood or not known by general consumers.

Patently Confusing Consumer Misconceptions and the Ways

Say consumers experiment with their home kitchenware using powerful neodymium magnets. They will even be convinced that their stainless steel products may not be authentic or safe even if there is a small amount of magnetic attraction on it. But practical metallurgical experience shows the opposite to be true.

In order to tackle customers issues in a practical manner:

- Do a magnetic attraction test against regular carbon steel items (like nails or screws) to see how strong the magnetism in your product is versus stainless steel. Even when 304 stainless steel is cold-worked, it will be much less magnetic than carbon steels or ferritic stainless steels such as grade 430.

- Show that magnetism as a result of cold working diminish with time, especially if the product undergoes heat treatments or is used for long time at high temperature (as is the case of cookware). This monotonically declining behavior proves that even mechanical deformation is the source of the magnetism to differentiate genuine austenitic stainless from specific magnetic alloys.

Case Study: Decorative Kitchen Utensils in Mechanical Deformation

Cookware sets made of true 304 stainless steel were stamped with mechanical forces applied as part of forming operations in a practical environment. The first magnet test was mild magnetic attraction, shocking consumers used to metallurgical knowledge.

However, prolonged use at cooking temperatures and routine thermal cycling in kitchens showed retests to have much reduced magnetism, confirming any strain induced magnetism would be transient, with little incremental risk in terms of product quality or safety. This hands-on experience makes the case for consumer awareness on all products marketed as stainless steel, which does not correlate with how magnetic they are.

Guidance for Consumers and Industries

As expert metallurgists and seasoned manufacturers would advise:

- Chill with Magnet Tests: Magnetism alone is an unreliable assessment for the quality or authenticity of stainless steel, the group says.

- Refer to product documentation and certifications: Check official product certificates or test reports from independent laboratories provided by reputable manufacturers to validate material specification.

- Real world significance: Mild magnetism from mechanical processing, or slight chemical variations, does not compromise performance, corrosion resistance, or product safety.

Concluding Remarks and Important Lessons

Overall, a little magnetism in ordinary non-magnetic-grade stainless steel products such as 304 as well as 201 alloys is scientifically understandable, not something to concern about, and usually fairly normal. The conditions from which magnetism usually occurs:

- Limited chemical compositional variation in production.

- Cold-working processes: Mechanical deformation.

- Temporary magnetic effects that decay gradually as time and usage accumulates.

Raising awareness for consumers and industry stakeholders alike at the realities of our industry helps dispel these myths in a manner that promotes consumer confidence and prevents unwarranted worries about product quality. Therefore, magnet tests should be only supplementary (not definitive) in the assessment of stainless products.

This holistic knowledge empowers consumers globally to recognize and endorse the authentic quality and performance of stainless steel offerings, regardless of instances of temporary magnetic properties manifesting in unexpected intervals.