When you are using stainless steel pans to cook skillfully, have you ever wondered how a stainless steel pot is made? How a simple piece of steel becomes a cooking tool we use every day? The manufacturing process of stainless steel pans is full of fine craftsmanship and professional technology. As a leading stainless steel kitchenware manufacturer from China, we are proficient in the process and knowledge of stainless steel manufacturing. We will share with readers how are stainless steel pans made? How to manufacture stainless steel?

The reputation of stainless steel cookware is that it lasts forever condensation, and excellent cooking performance. Every pot and pan we produce must meet these exacting standards, which is no small task – it’s a laborious process that happens behind the scenes. In this post, we will hence dive into the factory and follow each step of stainless steel cookware production—starting with raw materials to a shiny finished product. Knowing these, you will be able to understand the simple work put into product produces an offering appreciate how other pieces of cookware are made and also Identify high-quality stainless steel cookware on the market.

Stainless Steel Cookware Manufacturing Steps

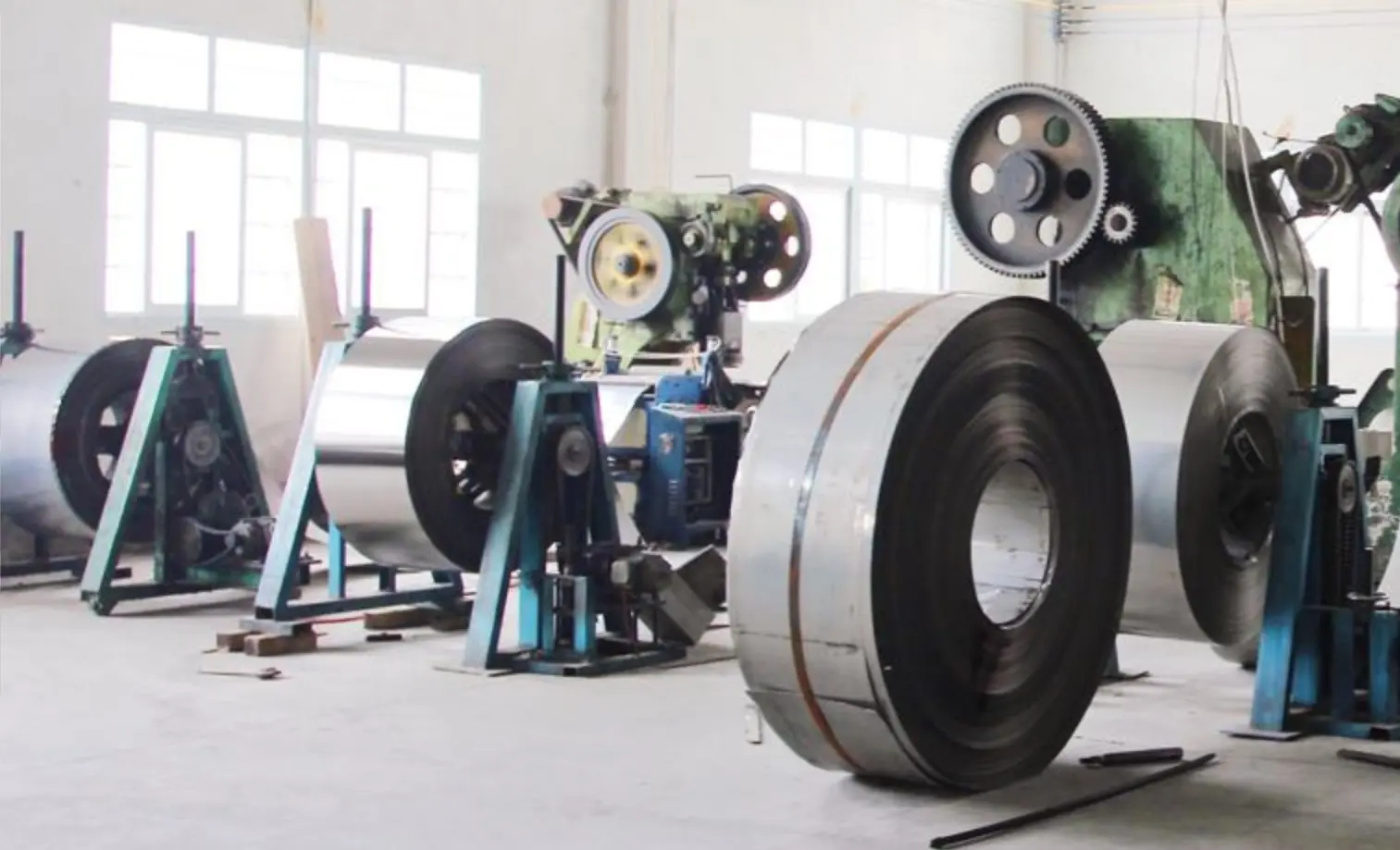

Step 1: Select High-Quality Stainless Steel Raw Materials

Stainless steel cookware quality starts with the choice of raw materials An alloy mainly of iron with 17 to 20% chromium and 8 to15%. Common grades used in cookware are 18/10 stainless steel, with 18% chromium and 10% nickel. The stainless steel is really stainless for its chromium makes it anti-corrosion and -rust, while the nickel gives it luster and improves corrosion resistance.

Stainless Steel Kitchenware Manufacturers will buy stainless steel from reliable materials Supplier. These raw materials must adhere to strict criteria regarding the ingredients and their purity. Impurities can compromise the performance and lifespan of all final products. Therefore, extensive testing and certification are needed before entering production mode.

Furthermore, it comes down to the quality of chromium and nickel used. The stainless steel is corrosion-resistant thanks to the high-purity chromium and possesses an attractive strength with a luster due to top-quality nickel. Certif i cates of analysis explaining compliance to the required specification are must be provided by suppliers for each batch of raw material.

Step 2: Cutting Stainless Steel Sheets

After the raw materials are prepared, they all need to be cut down. Stainless steel sheet of the desired grade is fed into a cutting machine which slices it in to predefined strips and sheets. The work must be done accurately, so that all parts pass to the following stages within defined parameters.

Techniques for laser cutting and plasma or hydraulic cutting are typically used. It is best suited for the intricate designs by providing them a very clean edge as well high precision which only laser cutting can deliver. Plasma cutting, in contrast, is much more cost-efficient when it comes to thicker plates and works considerably faster. Yes, hydraulic cutting uses fluids under pressure to cut the stainless steel and they make efficient work of these thicker cuts. What kind of cutting process is applied depends on the product specifications in each case.

During the laser cutting process, a high powered laser beam is directed along a precisely defined line on sheet steel to melt and vaporise it. This technique enables you to get accurate cuts with less no material wastage. Especially when creating ornamental designs and complicated patterns on the cookware surface.

The plasma cutting is used here where the high-velocity jet of ionized gas cuts through the stainless steel. This procedure is more effective as compared to the other and it can also work with sheets made of thicker stainless steel. It is usually for giant pieces of cookware which are not finely detailed.

Using the power of widened tap water to cut steel, hydraulic cutting applies high-pressure fluids in order to force on several pounds per square inch as a way through it speedily. This process is more productive in such a manner that it can be used on heavy plates and wide workpieces to deliver components of consistent dimensional accuracy.

Step 3: Grinding The Edge Of Stainless Steel Discs

The ends of the stainless steel pieces are usually rough and uneven after they have been cut. Grinding is then applied on those edges to make the pieces smooth and ready for further operation. This step is essential for your cookware to be safe and beautiful.

Abrasive belts or discs – constantly turning and rewoven with new abrasive layers as they wear down to eliminate more material while smoothing out flaws. You might need several stages of grinding so start with rough abrasives and then progress to finer ones. What this gives you is a flat surface that has no any sharp edges or burrs.

The grinding process is also key in obtaining the thickness and evenness desired for each piece of cookware. Each part is then meticulously measured and ground to the exact dimensions. This makes the final product consistent, whilst speeding up assembly at a later stage.

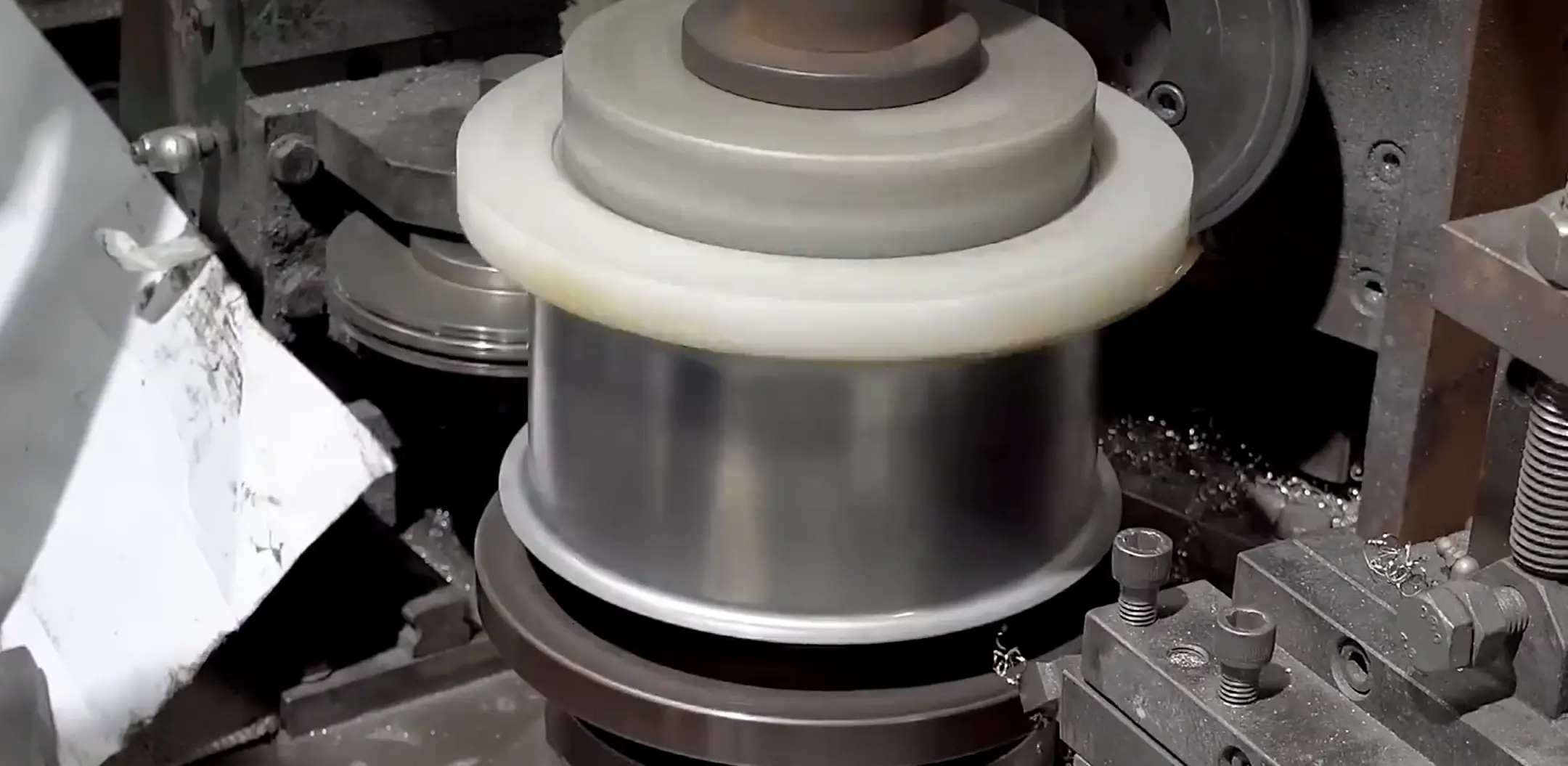

Step 4: Shaping the Cookware (Stretching)

Perhaps the most interesting phase is the stretching stage where flat stainless steel slabs ore shaped into recognizable pots, pans and other cookware pieces. The steel is then stretched and shaped into its required forms with the aid of powerful hydraulic presses. This takes a huge amount of force and exact measurements to make sure the sheets are uniform in width from end-to-end.

Stretching (Deep drawing) Basically a sheet of stainless steel is laid over a die, while the punch presses it into form. Repeated as necessary to arrive at the final contour with intermediate anneals for stress relief and formability.

Deep draw press utilizes stainless steel on which considerable pressure is exerted and this causes the material to flow into a die-shape. This requires precise control of the punch and die to maintain quality while avoiding unwanted effects like wrinkling or tearing. Lubricants are also important to help in friction-reduction and ensure that the stretching takes place smoothly.

Medium annealing comprises of heating the half-formed utensil to a set temperature after that hold up until it cools down. According to the company, this process reduces internal stresses resulting from stretching and increases ductility of material. This provides the stainless steel to shape additionally without breaking or cracking.

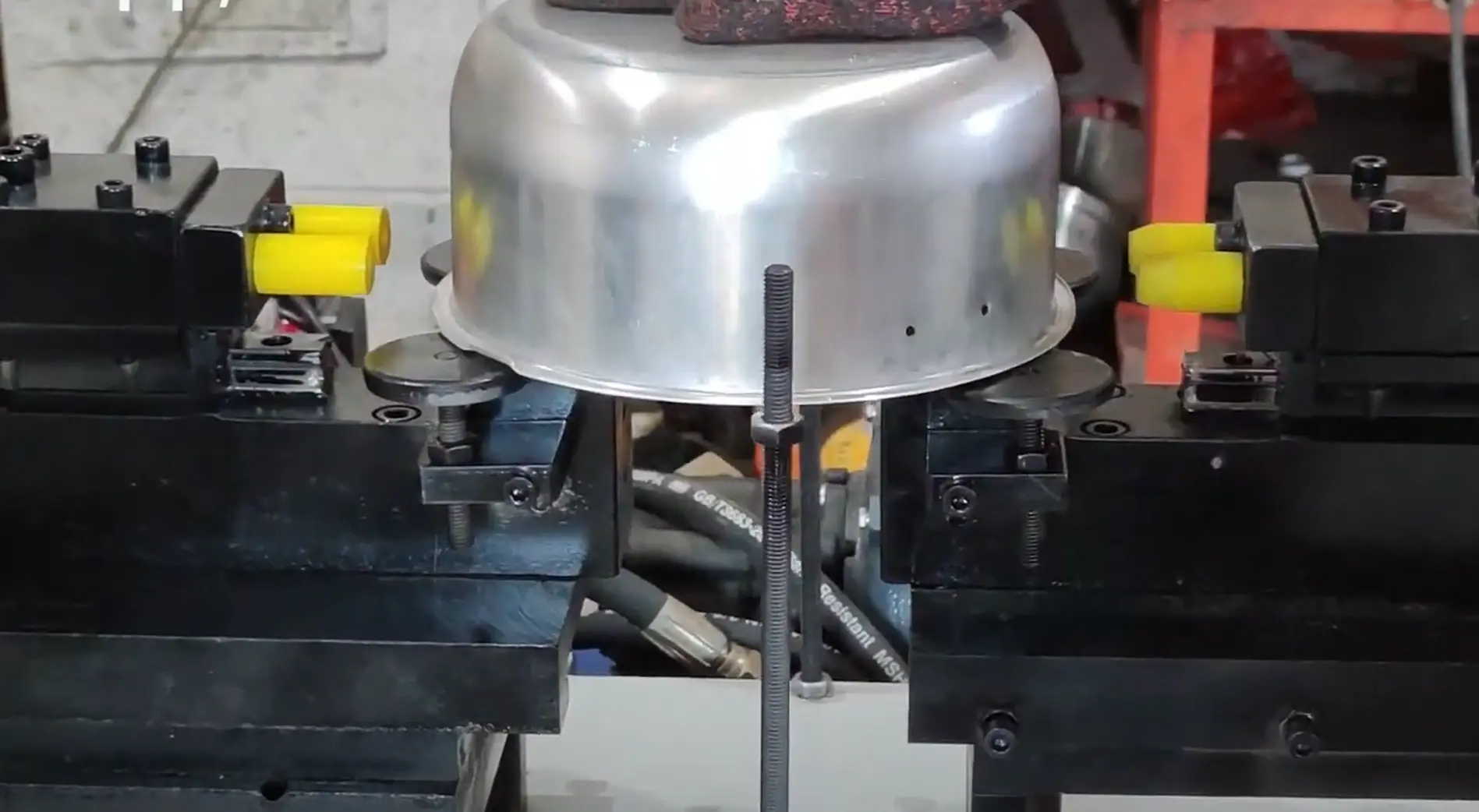

Step 5: Punching Holes in Stainless Steel Pots

During the punch process, features are added to your wares. Engraving can be for handles holes, rivets or some pattern on the surface. Each cookware piece is precisely lined up and punched to guarantee precision and consistency.

Punching machines Punches and dies are used to make holes with the desired format. For rivets, this means making certain that all holes are perfectly aligned to maintain proper fastening. Moreover, you can emboss a decorative pattern or logo into the surface to increase its aesthetic.

Modern punching machines have been provided with a number of dies and punches in order to carry out multiple operations simultaneously. It also increases efficiency and insures that every piece of cookware is manufactured to the same quality. The alignment and positioning of the punches are precisely regulated so that they do not allow any errors or misalignments.

Step 6: Trimming The Edges Of Cookware

The edges of the cookware pieces must be ejected and trimmed after stretching and punching to give them their final shape. Trimmers take away the additional material and smoothes out edges so every piece fits a final spec. There are no ways around this step as it is the thing that makes everything function and appear how you intended.

The process involves slashing utilizing sharp blades or rotary cutters to reduce the extra material. But it takes precision to make sure all the cookware pieces are alike, and that they are defect-free. A difference in the shape or size of these fingers can greatly affect performance and final appearance.

Trmming also includes deburring and recutting sharp edges created in the previous steps. That way the cookware remains protected for handling and usage. Trim edges are part inspected to the relevant specification.

Stpe 7: Cast Base — Maximized Heat Distribution

A feature of durable stainless steel cookware is the encapsulated base, otherwise known as cooks ware with “sandwich bottom” or composite base. In this configuration, conductive material (usually aluminum or copper) is encapsulated between stainless steel layers. With its encapsulated base, this model provides more efficient heat distribution throughout the pan so that nothing is going to be cold and uncooked while other parts will come out overdone.

Cast Basey generally has three steps, namely encapsulated bases, cladding, and impact bonding.

Encapsulated Bases: The first step in forming an encapsulated base is the preparation of a conductive core material. The aluminum and copper duo is selected for their superior thermal conductivity that facilitates efficient heat transfer, fast enough to level the temperature evenly. These metals get their names from the discs that are cut to match the dimensions of base circumference one such disc for wok electric stove tops@Column with a few lines Gem sentences.

The next step is to bond the conductive core with stainless steel. This is accomplished by a process known as cladding or impact bonding.

The cladding: The stainless steel into a conductive core and adjacent with hydraulic pressure rollers. They then go through a cluster of rollers and the pressure is so intense that it laminates all these layers into one sheet The cut discs from this laminated sheet provide the base of these utensils.

Impact Bonding: A second way to make an encapsulated base is by impact bonding. In this procedure, stainless steel and conductive core discs are aligned on top of each other then pressed under high-energy strikes – often hydraulic presses. The velocity of the collision fuses those layers together to form one hard, inflexible surface.

The base discs encapsulated inside the layers are then trimmed round and free of flash. At this stage you need to be precise; otherwise they would not look uniform and get proper fit with the cookware body.

The discs are then fixed into the utensil body. The usual approach is to use welding together with fastening methods for a reliable and isolation-free joint. To function best, it requires perfect alignment of the encapsulated base with the cookware body.

The quality of the encapsulated base is guaranteed to ensure the stability and performance of the stainless steel pot. This requires a number of tests, including:

Durability test: Durability test evaluates the pot’s ability to resist warping and deformation under high temperatures or frequent use.

Adhesion strength test: Ensures that the layers are well bonded and will not delaminate during use.

Thermal conductivity test: Measures the efficiency of the base in conducting heat.

Benefits of Encapsulated Bases

- Even Heat Distribution: The conductive core delivers even heat distribution across the entire cooking surface, eliminating hot spots and promoting equal-temperature cooktop.

- High Energy Efficiency:The faster and more efficient heat transfer means shorter cooking times, less energy wasted.

- Strengthened Sturdiness: The encased design boosts the structural stability of our pots and pans, meaning that they are virtually resistant to warping or breaking.

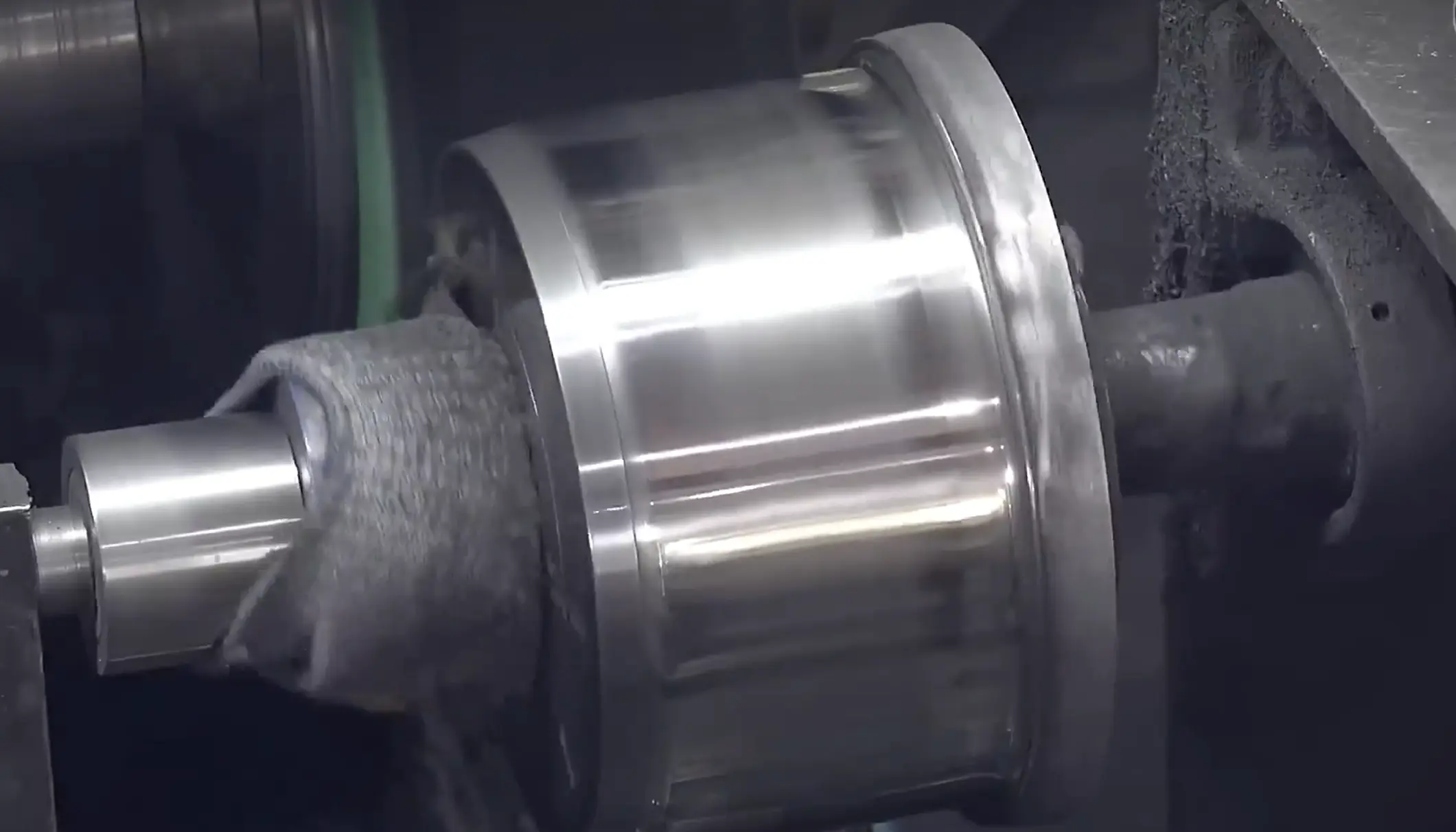

Step 8: Polish — High Mirror Finish

The polishing stage is the part where your cookware starts to get its trademark shine. This finish is extremely bright, requiring multiple levels of polishing and most commonly it is used in dust free environs. This flag isn’t just for looks though, it also acts an extra barrier of defense in preventing any corrosion.

Polishing is the process that produces a smooth, reflective surface by using abrasive compounds and buffing wheels. This is a process where the first abrasive used (the coarsest) removes various parts of your image, penetrating deeper than what you want. Subsequent abrasives are minimally less aggressive- each stage does progressively less damage to that full tangential area which was left by the previous operation in rougher fashion. In the last finishing step, fine-abrasive compounds are used for high-gloss polishing.

Polishing is a process, and one that takes time as well as skill to yield the desired outcome. After polishing, each piece of cookware is inspected and tested to guarantee that it meets our high standards. Dust-free environments are used to avoid contamination from dust, which in turn allows for a perfect finish.

Step 9: Add Handle

Handles make for convenient handling of Cookware, plus should give a different and elegant look as well. Manufacture of the cookware using built-in handles, where handles shall be welded or riveted carefully to bodies and they are attached in other processes called attachment. Handles need to be securely fixed, cool-to-the-touch and ergonomically designed for comfortable use in the attachment process.

For stainless steel handles, welding is the most common procedure as it makes them practically invulnerable by creating a strong bond that will last forever. This bonding process is performed by heating the handle and cookware body to a high temperature then welding them together. In contrast, riveting involves passing metal fasteners through pre-punched holes and then squeezing them together to hold both ends.

This is why strict control over heat input and weld speed during welding operations are essential in order to prevent any undesirable consequences, such as warping or weakened joints. Welded joints are also checked extensively to ensure they can hold up.

On the other hand,Rivetting has to be done very methodically in order for the rivets to be correctly lined up and registered before you tap them.

Heat-resistant handles are comfortable to hold, providing safer and easier cooking. Our ranges also have handles that are heat-resistant, and these products come with comfortable grip materials as well.

Step 10: Quality Inspection

Quality control constitutes an integral part of a production process. Every piece of cookware is carefully tested to perform at the highest level. They go through a process of imperfection check, thickness measurement and durability test. Anything that passed the points above will be packaged and shipped.

The double check… one through visual inspection and the other a mechanical process. The visual inspection detects surface defects including scratches, dents and discoloration. Conversely, mechanical inspections involve the measurement of thickness and weight to ensure that a specific standard is met. Careful attention is also paid to the results of durability tests performed on time, impact resistance and corrosion that verify cookware items can handle hard everyday use.

Particularly, only advanced quality control techniques like ultrasonic testing and X-ray inspection are used for this purpose because internal defects cannot be detected if they do not show on the surface. Both techniques offer a non-destructive way to assess the integrity of the cookware, guaranteeing that only top quality goods are sent out to patrons.

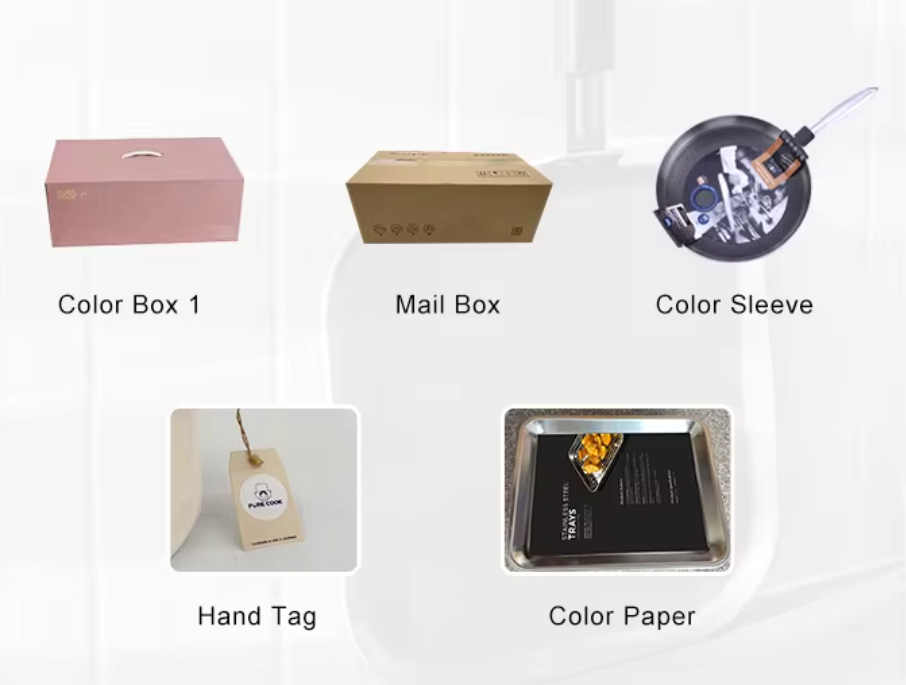

Step 11: Packing,Getting Ready for the Market

This is the final stage of production and involves packaging ready for being shipped to retailers/consumers. To avoid damaging the piece each one is carefully packaged anywhere. Packaging: which involves labeling and adding complementary items or documentation to the product.

At the time of packaging, we use material so that whatever your cookware is being carried in can be safely complimentary and if there will not make even a single scratchOrDent from it. The cookware is packed in sturdy boxes and sealed to prevent moisture or dust getting into them. Also, Labels are stitched to give information related to the product i.e. features, specifications and care instructions etc.

It even includes the addition of accessories, such as lids, handles or cleaning implements. Second, all of these have been tested and we only approve them if they operate to the same high standards as our cookware. From here, the final product is packaged and ready to be sent off to retailers nationwide & around the world!

Environmental Protection: Sustainable Manufacturing

The cookware industry has also been seeing an increasing focus on sustainable manufacturing practices in the past few years. In an effort to reduce their carbon footprint and have a more sustainable production, kitchenware manufacturers are adopting green manufacturing processes. This is achieved through use of recycles materials, reduction in energy consumption and minimization waste.

Since stainless steel can be melted down and used again without losing its quality is why people recycle it a lot. This lowers the need for virgin resources, preserving natural raw materials. Additionally, energy-saving activities are carried out by manufacturers both in terms of installing renewable power sources and improvements to optimize the production schedule as a means to reduce energy consumption.

Another important measure in sustainable manufacturing is waste reduction.Stainless steel kitchenware manufacturers work to keep waste down by using materials as efficiently as possible, repurposing scrap metal. It also use waste management policies to lessen and properly disposal of any produced wastes.

Innovation in Cookware Design

The cookware industry has always been changing, with manufacturers challenging themselves to make their products offer the best performance and utility. This includes using innovative design elements and advanced materials to improve cooking performance and durability.

Tri-ply and multi-ply cookware: These are only a few designs that enhance heat dispersion for less cooking time. These stainless steel pots and pans have several layers, which include stainless along with other metals like aluminum or copper to provide superior conductive features and even cooking.

Nonstick coatings also advance. Newer non-stick coatings, on the other hand, are now formulated to last much longer and be less prone to scratching or peeling. Also, most are cooking safe as they do not contain the harmful PFOA and PFOS chemicals.

Conclusion

Stainless steel cookware is a challenging set of products which require both advanced technology and fine craftsmanship. Quality and performance were the goals from raw material selection through final polish. If you follow this guide, after knowing these processes will know how valuable and skillful the cookware that you use every day was made. When you are looking for the most excellent stainless steel cookware to fit in any professional or home kitchen, it should be a type of investment which will continue serving your purpose over time if not forever.

Submit Your Custom Kitchenware Ideas

Are you inspired by the meticulous production of stainless steel cookware? Do you have a specific style or plan for your kitchen? PURECOOK offers custom stainless steel cookware, and all of our cookware is designed and manufactured with durable quality.

We offer unlimited customization options. You can design a cookware product from any dimension, such as material, size, coating, color, etc. Our expert team and professional production line provide you with the best support throughout the process.

From hotels that lack high-quality bulk cookware, to cooking enthusiasts seeking clever tools that are not currently available on the market, or even any retailer who wants to obtain and offer unique new products. Whatever help you need, our expert team will help you in every link from design to production.

About Purecook

Purecook is one of the most well-known kitchenware manufacturers in China. In the past 30 years, we have provided OEM & ODM custom kitchenware solutions for large and small companies around the world. We always maintain efficient collaboration and best partner relationship with clients. Even if clients are not clear about what kind of kitchenware their business needs, we also rely on professional knowledge and ability to help clients better understand the market situation, which is why we have gained the trust of many clients.

In fact, we have diverse capabilities. We have a professional R&D team composed of designers, material experts, and technicians, so we can do light customization and deep customization. We have manufactured more than 550 styles of professional kitchenware series to meet the needs of buyers in most regions.

We have the industry’s leading professional production line, and have established a strict quality inspection system to conduct 100% quality inspection on products. Our wholesale cookware products are well praised for their high quality and long service life.

In terms of service, our camera team provides Amazon sellers with free high-quality picture shooting services and product video optimization services.

Contact Us Today

Stop compromising with unsatisfactory cookware in the market. CONTACT US!! todiscuss your requirements and for a quote on custom Stainless Steel Cookware. Visit our website at http://www. purecook. com to get your conversation started. Join us and let’s start working together on cookware that lives up to your potential!

Contact Us

Don’t hesitate to call usjoy@purecook.com

Don’t hesitate to contact usNo.68 Xianhua Road,HuaqiaoVillage,Caitang Town,Chao'an District,Cha ozhou City,Guangdong Province